In today's competitive landscape, small and medium-sized businesses (SMBs) in the UK and EU are increasingly adopting Lean principles to streamline operations and eliminate waste in their supply chains. By focusing on efficiency and value creation, these businesses can enhance profitability and customer satisfaction.

Understanding Lean Principles

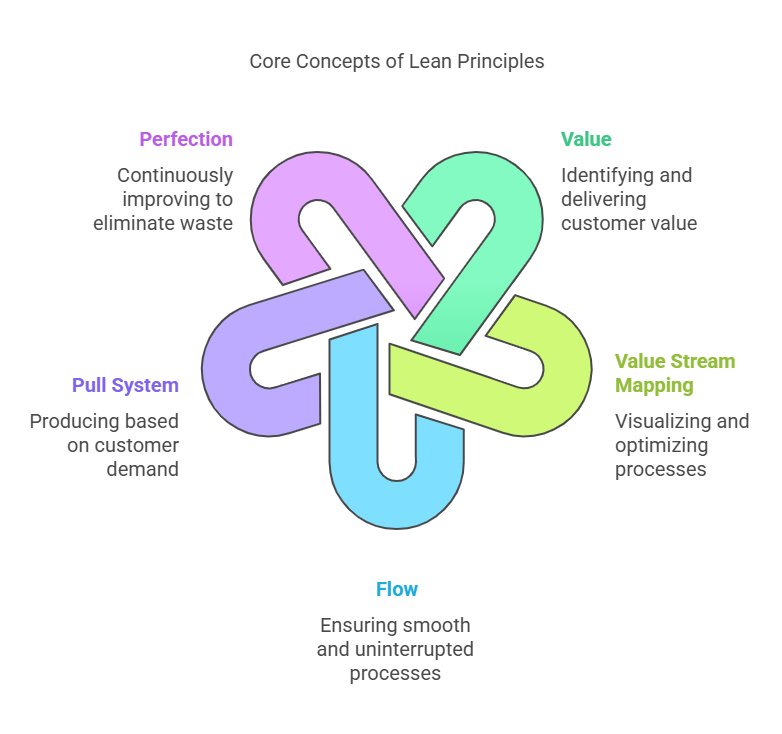

Lean principles, originating from the Toyota Production System, emphasize the elimination of waste and the continuous improvement of processes. The core concepts include:

Value:Identifying what the customer values and ensuring that all processes contribute to delivering this value.

Value Stream Mapping:Visualizing the flow of materials and information to identify and eliminate non-value-adding activities.

Flow:Ensuring that processes operate smoothly without interruptions.

Pull System:Producing only what is needed by the customer, reducing overproduction and inventory costs.

Perfection: Continuously improving processes to achieve the ideal state of zero waste.

Case Study: Mattel's Agile Supply Chain Transformation

Mattel, a leading toy manufacturer, faced challenges in responding swiftly to market demands, particularly highlighted by the unexpected popularity of the "Weird Barbie" doll following the "Barbie" movie release. To address this, Mattel undertook a comprehensive transformation of its supply chain to enhance agility and responsiveness.

Mattel aimed to redesign its supply chain to enable rapid production and distribution of products in response to unforeseen demand spikes. The goal was to reduce lead times, enhance production flexibility, and improve inventory management to better align with market dynamics.

To achieve these objectives, Mattel implemented several strategic initiatives:

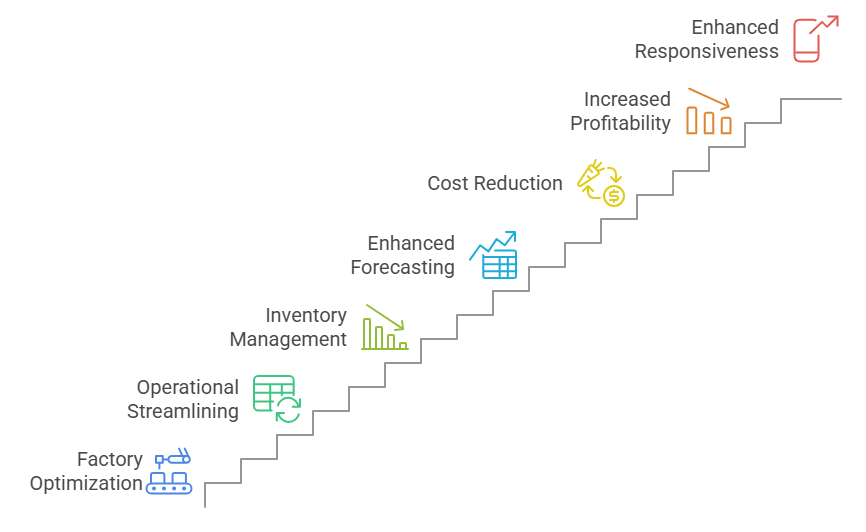

Factory Optimization:The company closed less productive factories and outsourced production to specialized partners, streamlining operations and focusing on key manufacturing sites.

Operational Streamlining:Mattel restructured its operations at critical sites to enhance efficiency, reduce bottlenecks, and improve overall production flow.

Inventory Management:The company reduced inventory levels by eliminating less popular items, allowing for a more responsive approach to market demands.

Enhanced Forecasting:Mattel improved its forecasting capabilities to better anticipate consumer trends and adjust production schedules accordingly.

These strategic actions led to significant improvements in Mattel's supply chain performance:

Cost Reduction:The company achieved cost savings through operational efficiencies and reduced inventory holding costs.

Increased Profitability:Despite a decline in overall sales, Mattel's gross margin improved, indicating more profitable operations.

Enhanced ResponsivenessThe agile supply chain enabled Mattel to quickly capitalize on viral trends, such as the "Weird Barbie" doll, leading to timely product launches and increased market share.

Benefits of Lean Supply Chain Management

Implementing Lean principles offers several advantages for SMBs:

Cost Reduction: Eliminating waste and optimizing processes can lead to significant operational cost savings.

Improved Efficiency: Streamlined processes result in faster production times and quicker delivery to customers.

Enhanced Customer Satisfaction:Delivering value efficiently ensures that customer needs are met promptly and effectively.

Increased Flexibility:Lean supply chains can quickly adapt to changes in demand or market conditions.

Steps to Implement Lean Principles

For SMBs looking to adopt Lean principles, consider the following steps:

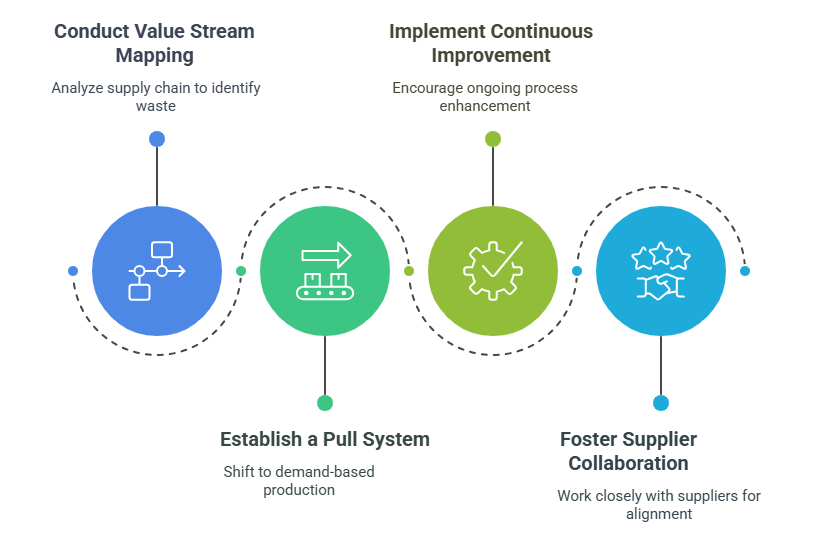

Conduct Value Stream Mapping: Analyze your supply chain to identify areas of waste and inefficiency.

Establish a Pull System:Shift from a push system to a pull system, producing based on actual customer demand.

Implement Continuous Improvement:Encourage a culture of ongoing process enhancement through regular reviews and employee involvement.

Foster Supplier Collaboration:Work closely with suppliers to ensure alignment with Lean principles, leading to better quality materials and reduced lead times.

Conclusion

Adopting Lean principles enables SMBs in the UK and EU to create more efficient, cost-effective, and customer-centric supply chains. By focusing on value creation and continuous improvement, businesses can achieve a competitive edge in the marketplace.

Write a comment